Rectangular Profile Spring Washers (DIN 127B)

DIN127(B) spring washers

|

standard

DIN127.pdf

|

name

Spring washers, heavy duty spring washers

|

English name

Spring Washer |

|

Approximate Standard

GB93.pdf

|

Material

Stainless steel, nonferrous metals, etc.

|

surface

Natural color, passivation, electroplating...

|

|

Performance level

|

Application Areas

Bolt connection, nut connection

|

|

Spring washers are mainly used for screws and are often used in conjunction with flat washers. They produce elastic deformation through the shape of the spring, and under the action of preload, they generate a certain tightening force, thus effectively preventing the loosening of the bolt connection.

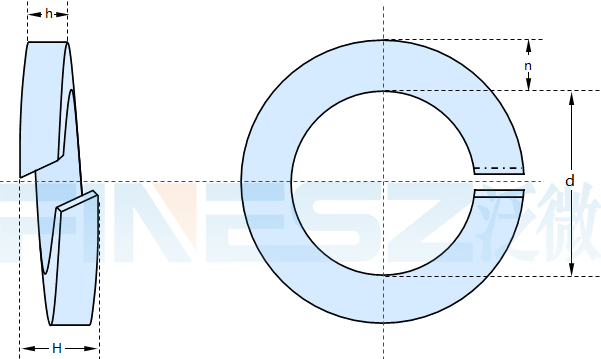

DIN 127 spring washers specify the dimensions and material grades of spring washers. DIN 127 spring washers are divided into two series, A and B. DIN 127A (standard): Single-bend spring washers with flat ends, similar to GB93, suitable for most standard applications. DIN 127B (load-bearing or heavy-duty): Single-bend spring washers with square ends, primarily used in applications requiring higher loads.

This page introduces DIN127 Type B.

Download the original German standard document: DIN127.pdf

drawing:

Size table (unit: MM)

| Nominal Diameter | F2 | Φ2.2 | Φ2.5 | F3 | Φ3.5 | F4 | F5 | F6 | F7 | F8 | F10 | F12 | F14 | F16 | F18 | F20 | F22 | Φ24 | F27 | Φ30 | Φ36 | F39 | F42 | Φ45 | F48 | F52 | F56 | Φ60 | Φ64 | Φ68 | Φ72 | Φ80 | Φ90 | Φ100 | |

| d | Minimum | 2.1 | 2.3 | 2.6 | 3.1 | 3.6 | 4.1 | 5.1 | 6.1 | 7.1 | 8.1 | 10.2 | 12.2 | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 | 24.5 | 27.5 | 30.5 | 36.5 | 39.5 | 42.5 | 45.5 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 81 | 91 | 101 |

| Maximum | 2.4 | 2.6 | 2.9 | 3.4 | 3.9 | 4.4 | 5.4 | 6.5 | 7.5 | 8.5 | 10.7 | 12.7 | 14.7 | 17 | 19 | 21.2 | 23.5 | 25.5 | 28.5 | 31.7 | 37.7 | 40.7 | 43.7 | 46.7 | 50.5 | 54.5 | 58.5 | 62.5 | 66.5 | 70.5 | 74.5 | 82.5 | 92.5 | 103 | |

| n | Nominal | 0.9 | 1 | 1 | 1.3 | 1.3 | 1.5 | 1.8 | 2.5 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| Maximum | 1 | 1.1 | 1.1 | 1.4 | 1.4 | 1.6 | 1.9 | 2.65 | 2.65 | 3.15 | 3.7 | 4.2 | 4.7 | 5.2 | 5.2 | 6.2 | 6.2 | 7.25 | 7.25 | 8.25 | 10.3 | 10.3 | 12.3 | 12.3 | 12.3 | 14.3 | 14.3 | 14.3 | 14.3 | 14.3 | 14.3 | 14.3 | 14.3 | 14.3 | |

| Minimum | 0.8 | 0.9 | 0.9 | 1.2 | 1.2 | 1.4 | 1.7 | 2.35 | 2.35 | 2.85 | 3.3 | 3.8 | 4.3 | 4.8 | 4.8 | 5.8 | 5.8 | 6.75 | 6.75 | 7.75 | 9.75 | 9.75 | 11.8 | 11.8 | 11.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | 13.8 | |

| h | Nominal | 0.5 | 0.6 | 0.6 | 0.8 | 0.8 | 0.9 | 1.2 | 1.6 | 1.6 | 2 | 2.2 | 2.5 | 3 | 3.5 | 3.5 | 4 | 4 | 5 | 5 | 6 | 6 | 6 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Maximum | 0.6 | 0.7 | 0.7 | 0.9 | 0.9 | 1 | 1.3 | 1.7 | 1.7 | 2.1 | 2.35 | 2.65 | 3.15 | 3.7 | 3.7 | 4.2 | 4.2 | 5.2 | 5.2 | 6.2 | 6.2 | 6.2 | 7.25 | 7.25 | 7.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | 8.25 | |

| Minimum | 0.4 | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 1.1 | 1.5 | 1.5 | 1.9 | 2.05 | 2.35 | 2.85 | 3.3 | 3.3 | 3.8 | 3.8 | 4.8 | 4.8 | 5.8 | 5.8 | 5.8 | 6.75 | 6.75 | 6.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | 7.75 | |

| H | Minimum | 1 | 1.2 | 1.2 | 1.6 | 1.6 | 1.8 | 2.4 | 3.2 | 3.2 | 4 | 4.4 | 5 | 6 | 7 | 7 | 8 | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Maximum | 1.2 | 1.4 | 1.4 | 1.9 | 1.9 | 2.1 | 2.8 | 3.8 | 3.8 | 4.7 | 5.2 | 5.9 | 7.1 | 8.3 | 8.3 | 9.4 | 9.4 | 11.8 | 11.8 | 14.2 | 14.2 | 14.2 | 16.5 | 16.5 | 16.5 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | |

| Thousand pieces weight (steel) ≈ kg | 0.03 | 0.05 | 0.05 | 0.11 | 0.12 | 0.18 | 0.36 | 0.83 | 0.93 | 1.6 | 2.53 | 3.82 | 6.01 | 8.91 | 9.73 | 15.2 | 16.5 | 26.2 | 28.7 | 44.3 | 67.3 | 71.7 | 111 | 117 | 123 | 182 | 193 | 203 | 218 | 228 | 240 | 262 | 290 | 318 | |

①, Material:

FST = Spring steel according to DIN 267-26

DIN 267-26 : Spring washers should be made of spring steel (FSt) in accordance with DIN 17 221 or DIN 17 222 ; Spring washers hardness HV430-530