Flat Washers (DIN 9021)

DIN9021-1990 flat washer

|

standard

DIN9021.pdf

|

name

Large flat washer

|

English name

Plain Washer Large series

|

|

Approximate Standard

GB/T96.1.pdf , ISO7093-1.pdf

|

Material

Stainless steel, nonferrous metals, etc.

|

surface

Natural color, passivation, electroplating...

|

|

Performance level

|

Application Areas

Bolt connection, nut connection

|

|

Compared to standard size flat washers (such as DIN125 , GB97.1 , etc.), the DIN9021 flat washer has a larger outer diameter. This design provides a larger support area, helps to disperse the pressure of the fastener and reduce damage to the fixed material.

Due to their large outer diameter, DIN9021 flat washers are widely used in situations where a larger bearing surface is required, such as in metal structures, mechanical equipment, automobiles, construction and other fields.

Like other flat washers, DIN9021 flat washers are very easy to install. Just place them between the bolt and the fixed part.

Download the original German standard document: DIN9021.pdf

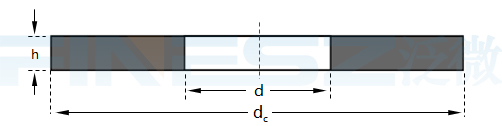

drawing:

Size table (unit: MM)

| Nominal diameter | |

| For thread diameter | |

| d | Minimum value = nominal |

| Maximum | |

| dc | Maximum value = nominal |

| Minimum | |

| h | Nominal |

| Maximum | |

| Minimum | |

| Thousand pieces weight (steel) ≈ kg | |

| 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 20 | twenty two | 26 | 33 | 39 |

| 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | twenty four | 30 | 36 |

| 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 20 | twenty two | 26 | 33 | 39 |

| 2.84 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | 10.77 | 13.27 | 15.27 | 17.27 | 20.52 | 22.52 | 26.84 | 34 | 40 |

| 8 | 9 | 11 | 12 | 15 | 18 | twenty two | twenty four | 30 | 37 | 44 | 50 | 56 | 60 | 72 | 92 | 110 |

| 7.64 | 8.64 | 10.57 | 11.57 | 14.57 | 17.57 | 21.48 | 23.48 | 29.48 | 36.38 | 43.38 | 49.38 | 54.1 | 58.1 | 70.1 | 89.8 | 107.8 |

| 0.8 | 0.8 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2 | 2.5 | 3 | 3 | 3 | 4 | 4 | 5 | 6 | 8 |

| 0.9 | 0.9 | 0.9 | 1.1 | 1.4 | 1.8 | 2.2 | 2.2 | 2.7 | 3.3 | 3.3 | 3.3 | 4.6 | 4.6 | 6 | 7 | 9.2 |

| 0.7 | 0.7 | 0.7 | 0.9 | 1 | 1.4 | 1.8 | 1.8 | 2.3 | 2.7 | 2.7 | 2.7 | 3.4 | 3.4 | 4 | 5 | 6.8 |

| 0.28 | 0.349 | 0.529 | 0.774 | 1.46 | 2.79 | 5.29 | 6.23 | 12.2 | 22.2 | 31.6 | 40.9 | 67.4 | 76.8 | 139 | 273 | 522 |

①, Materials:

a) Steel, hardness grade: 140HV; hardness range HV10: 140~250

b) Stainless steel, hardness grade: 140HV; hardness range HV10: 140~250; Steel group: A2, A4, F1, C1, C4 according to DIN 267-11

c) Non-ferrous metals and other materials as agreed

| Material | steel | Stainless steel | |

| hardness |

A: 140 HV C: 100 HV |

140 HV | |

| Hardness range |

A: 140 ~ 250 HV10 C: 100 ~ 250 HV10 |

140 ~ 250 HV10 | |

| Mechanical properties | Material (steel group) | / | A2, A4, F1, C1, C4 |

| standard | / | DIN 267 part 11 | |

| tolerance | Product Grade |

A: ≤ 17 C: > 17 |

|

| standard | DIN 522 | ||

| Surface treatment |

Blank electroplating DIN 267 part 9 Other surface treatments shall be agreed upon by both parties. |

||

| surface roughness | DIN 522 | ||

| Acceptance and packaging | DIN 522 | ||