Internal Locking Washers (DIN 6797J)

DIN6797J-1988 Internal tooth lock washers

|

standard

DIN6797J-1988

|

name

Internal tooth lock washers

|

English name

Toothed lock washers internal Form J

|

|

Material

Stainless steel, etc.

|

surface

Natural color, passivation, electroplating...

|

Application Areas

Wind power generation, medical machinery

|

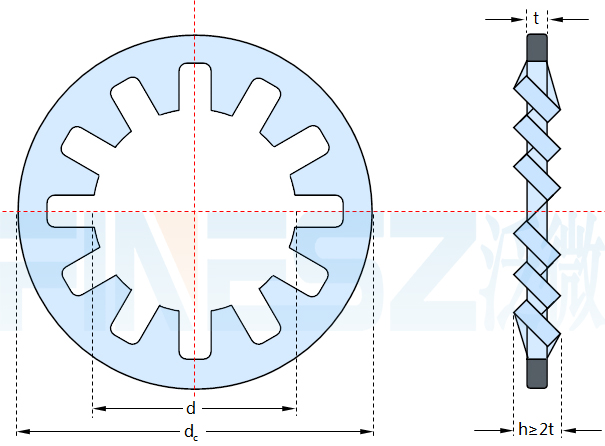

DIN6797J internal tooth lock washers are washers that use multiple small teeth on the inside to solve the problem of screw loosening. When tightening the screw, the teeth will "bite" into the parts and screw heads, providing double anti-loosening by interlocking + friction. The teeth are hidden inside and will not scratch the parts, making them suitable for small spaces.

The sizes range from M2 to M30 and the thickness ranges from 0.3 to 1.6 mm. It is now used in machine power parts (automobile engines, machine tool gearboxes), precision small parts (mobile phones, servers), power grounding interfaces, as well as aircraft, high-speed rail, etc.

High-risk scenarios, adapted to different needs.

drawing:

Size table (unit: MM)

| Specification | |

| d | Minimum value = nominal |

| Maximum | |

| d c | Maximum value = nominal |

| Minimum | |

| t | |

| Number of teeth | |

| Thousand pieces weight kg | |

| Applicable thread | |

| 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 19 | twenty one | twenty three | 25 | 28 | 31 |

| 2.2 | 2.7 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 19 | twenty one | twenty three | 25 | 28 | 31 |

| 2.34 | 2.84 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | 10.77 | 13.27 | 15.27 | 17.27 | 19.33 | 21.33 | 23.33 | 25.33 | 28.33 | 31.39 |

| 4.5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 12.5 | 15 | 18 | 20.5 | twenty four | 26 | 30 | 33 | 36 | 38 | 44 | 48 |

| 4.2 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.07 | 14.57 | 17.57 | 19.98 | 23.48 | 25.48 | 29.48 | 32.38 | 35.38 | 37.38 | 43.38 | 47.38 |

| 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 | 0.8 | 0.9 | 1 | 1 | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 |

| 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 9 | 10 | 10 | 12 | 12 | 12 | 14 | 14 | 14 | 14 |

| 0.04 | 0.045 | 0.045 | 0.085 | 0.1 | 0.2 | 0.25 | 0.35 | 0.55 | 0.9 | 1.2 | 1.9 | 2.4 | 3.7 | 4.1 | 6 | 6.5 | 8.5 | 9.5 |

| M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 |

①, Materials see "Related Material Standards and Brands", the material brand is selected by the manufacturer; Hardness: 350~425 HV10