Flat Washers (DIN 125)

DIN125-1990 flat washer

|

standard

DIN125.pdf

|

name

flat washers

|

English name

Washer |

|

Approximate Standard

GB/T97.1 , GB/T97.2 , ISO7089-2000

|

Material

Stainless steel, nonferrous metals, etc.

|

surface

Natural color, passivation, electroplating...

|

|

Performance level

|

Application Areas

Bolt connection, nut connection

|

|

DIN125 flat washers are a commonly used type of washer fastener used in the connection between bolts or nuts and the surface of the locked parts. They increase the contact area of the locked parts and disperse the pressure, reduce the friction between the bolts and the locked parts, protect the surface of the locked parts from wear and damage, and play a role in preventing loosening to a certain extent.

Download the original German standard document: DIN125.pdf

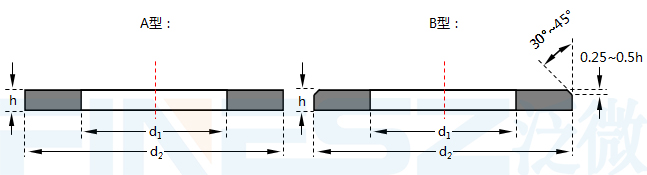

drawing:

Size table (unit: MM)

| Specification | |

| M | Corresponding bolt specifications |

| d 1 | Minimum value = nominal |

| Maximum | |

| d 2 | Maximum value = nominal |

| Minimum | |

| h | Nominal |

| Maximum | |

| Minimum | |

| Thousand pieces weight (steel) ≈ kg | |

| Φ1.7 | Φ1.8 | Φ2.2 | Φ2.5 | Φ2.7 | Φ2.8 | Φ3.2 | Φ3.7 | Φ4.3 | Φ5.3 | Φ6.4 | Φ7.4 | Φ8.4 | Φ10.5 | F13 | F15 | F17 | F19 | F21 | F23 | Φ25 | F27 | F28 | F29 | F31 | F33 | Φ34 | Φ36 | F37 | F39 | Φ40 | F41 | F43 | F46 | Φ50 | F52 | F54 | F57 | F58 | Φ60 | Φ62 | Φ66 | Φ70 | Φ74 | F78 | Φ82 | F87 | F93 | F98 | Φ104 | F109 | Φ114 | F119 | Φ124 | F129 | Φ134 | F139 | Φ144 | Φ149 | Φ155 | Φ165 |

| M1.6 | M1.7 | M2 | M2.3 | M2.5 | M2.6 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M26 | M27 | M28 | M30 | M32 | M33 | M35 | M36 | M38 | M39 | M40 | M42 | M45 | M48 | M50 | M52 | M55 | M56 | M58 | M60 | M64 | M68 | M72 | M76 | M80 | M85 | M90 | M95 | M100 | M105 | M110 | M115 | M120 | M125 | M130 | M135 | M140 | M145 | M150 | M160 |

| 1.7 | 1.8 | 2.2 | 2.5 | 2.7 | 2.8 | 3.2 | 3.7 | 4.3 | 5.3 | 6.4 | 7.4 | 8.4 | 10.5 | 13 | 15 | 17 | 19 | 21 | 23 | 25 | 27 | 28 | 29 | 31 | 33 | 34 | 36 | 37 | 39 | 40 | 41 | 43 | 46 | 50 | 52 | 54 | 57 | 58 | 60 | 62 | 66 | 70 | 74 | 78 | 82 | 87 | 93 | 98 | 104 | 109 | 114 | 119 | 124 | 129 | 134 | 139 | 144 | 149 | 155 | 165 |

| 1.84 | 1.94 | 2.34 | 2.64 | 2.84 | 2.94 | 3.38 | 3.88 | 4.48 | 5.48 | 6.62 | 7.62 | 8.62 | 10.77 | 13.27 | 15.27 | 17.27 | 19.33 | 21.33 | 23.33 | 25.33 | 27.33 | 28.33 | 29.33 | 31.39 | 33.62 | 34.62 | 36.62 | 37.62 | 39.62 | 40.62 | 41.62 | 43.62 | 46.62 | 50.62 | 52.74 | 54.74 | 57.74 | 58.74 | 60.74 | 62.74 | 66.74 | 70.74 | 74.74 | 78.74 | 82.87 | 87.87 | 93.87 | 98.87 | 104.9 | 109.9 | 114.9 | 119.9 | 125 | 130 | 135 | 140 | 145 | 150 | 156 | 166 |

| 4 | 4.5 | 5 | 6 | 6 | 7 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 20 | 24 | 28 | 30 | 34 | 37 | 39 | 44 | 50 | 50 | 50 | 56 | 60 | 60 | 66 | 66 | 72 | 72 | 72 | 78 | 85 | 92 | 92 | 98 | 105 | 105 | 110 | 110 | 115 | 120 | 125 | 135 | 140 | 145 | 160 | 165 | 175 | 180 | 185 | 200 | 210 | 220 | 220 | 230 | 240 | 250 | 250 | 250 |

| 3.7 | 4.2 | 4.7 | 5.7 | 5.7 | 6.64 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | 13.57 | 15.57 | 19.48 | 23.48 | 27.48 | 29.48 | 33.38 | 36.38 | 38.38 | 43.38 | 49.38 | 49.38 | 49.38 | 55.26 | 58.8 | 58.8 | 64.8 | 64.8 | 70.8 | 70.8 | 70.8 | 76.8 | 83.6 | 90.6 | 90.6 | 96.6 | 103.6 | 103.6 | 108.6 | 108.6 | 113.6 | 118.6 | 123.4 | 133.4 | 138.4 | 143.4 | 158.4 | 163.4 | 173.4 | 178.4 | 183.2 | 198.15* | 208.2 | 218.2 | 218.2 | 228.2 | 238.2 | 248.2 | 248.2 | 248.2 |

| 0.3 | 0.3 | 0.3 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 1 | 1.6 | 1.6 | 1.6 | 2 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 7 | 7 | 8 | 8 | 8 | 9 | 9 | 9 | 9 | 9 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 18 | 18 | 18 | 18 |

| 0.35 | 0.35 | 0.35 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.9 | 1.1 | 1.8 | 1.8 | 1.8 | 2.2 | 2.7 | 2.7 | 3.3 | 3.3 | 3.3 | 3.3 | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 | 5.6 | 5.6 | 5.6 | 5.6 | 6.6 | 6.6 | 6.6 | 8 | 8 | 9 | 9 | 9 | 10 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 13.2 | 13.2 | 13.2 | 13.2 | 15.2 | 15.2 | 15.2 | 15.2 | 17.2 | 17.2 | 17.2 | 17.2 | 19.2 | 19.2 | 19.2 | 19.2 |

| 0.25 | 0.25 | 0.25 | 0.45 | 0.45 | 0.45 | 0.45 | 0.45 | 0.7 | 0.9 | 1.4 | 1.4 | 1.4 | 1.8 | 2.3 | 2.3 | 2.7 | 2.7 | 2.7 | 2.7 | 3.7 | 3.7 | 3.7 | 3.7 | 3.7 | 4.4 | 4.4 | 4.4 | 4.4 | 5.4 | 5.4 | 5.4 | 6 | 6 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | 10.8 | 10.8 | 10.8 | 10.8 | 12.8 | 12.8 | 12.8 | 12.8 | 14.8 | 14.8 | 14.8 | 14.8 | 16.8 | 16.8 | 16.8 | 16.8 |

| 0.024 | 0.031 | 0.037 | 0.092 | 0.088 | 0.127 | 0.119 | 0.155 | 0.308 | 0.443 | 1.02 | 1.39 | 1.83 | 3.57 | 6.27 | 8.62 | 11.3 | 14.7 | 17.2 | 18.3 | 32.3 | 43.7 | 42.3 | 40.9 | 53.6 | 77.4 | 75.3 | 94.3 | 92.1 | 136 | 133 | 130 | 183 | 220 | 294 | 284 | 330 | 431 | 425 | 472 | 458 | 492 | 586 | 626 | 749 | 953 | 996 | 1250 | 1300 | 1710 | 1770 | 1830 | 2230 | 2830 | 3130 | 3000 | 3310 | 4090 | 4470 | 4270 | 3910 |

①. The original standard specifies a minimum dc value of 188.15 for Φ119, but the corresponding deviation here is 1.85mm, meaning the actual minimum is 200-1.85 = 198.15mm. (DIN 522 stipulates that when h is less than 4 and the product grade is A, the dimensional tolerance for d2 is h15. When dc is 200mm, the corresponding deviation is 1.85mm.)

②, Materials:

1) Steel hardness grade 140HV, hardness HV140-250; hardness grade 200HV, hardness HV200-250

2) Stainless steel hardness grade 140HV, hardness HV140-250; hardness grade 200HV, hardness HV200-250; stainless steel groups A2 and A4, F1, C1 and C4

3) Gaskets may be made of non-ferrous metals or other materials according to the agreement

4) When h does not exceed 0.5 mm, the hardness grade is HV2, and when h exceeds 0.5 mm, the hardness grade is HV10. (See original technical conditions)

| Materials ① | type | steel | Stainless steel | ||

| Mechanical properties | Hardness grade | 140 HP | 200 HP | 140 HP | 200 HP |

| Hardness range② | 140 HP~250 HP | 200HP~250HP | 140 HP~250 HP | 200HP~250HP | |

| Material (steel group) | / | A2 and A4 F1 C1 and C4 | |||

| As specified in | / | DIN 267 Part 11 | |||

| tolerance | Product Grade | A | |||

| standard | DIN522 | ||||

| Surface treatment |

Bright. Surface roughness DIN522 Electroplating DIN 267 part 9 If other surface treatment is required, it should be agreed upon by both parties. |

||||

| Acceptance and packaging | DIN522 | ||||

| illustrate | ① Washers may be made of non-ferrous metals or other materials, subject to agreement. ② For h not exceeding 0.5 mm, the hardness shall be HV 2 and for h exceeding 0.5 mm, HV 10. |

||||